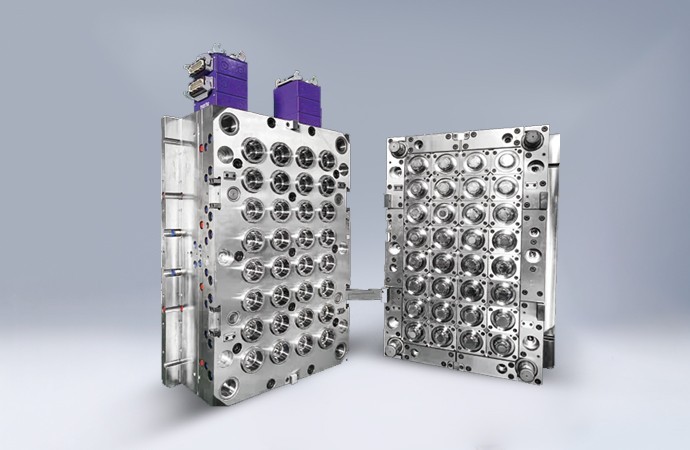

Quality Inspection

In the process of mold manufacturing, quality inspection is a very important link.

We strictly test raw materials, heat treatment, equipment accuracy, processing accuracy, surface treatment, products and other aspects, and all parts must be inspected.

Can proceed to the next process. The mold quality control method adopts the self-inspection of workers, the first inspection of the quality inspector in each process, the inspection of the quality inspector in the processing process and the final inspection of the quality inspector after completion to ensure the stability and reliability of the mold.